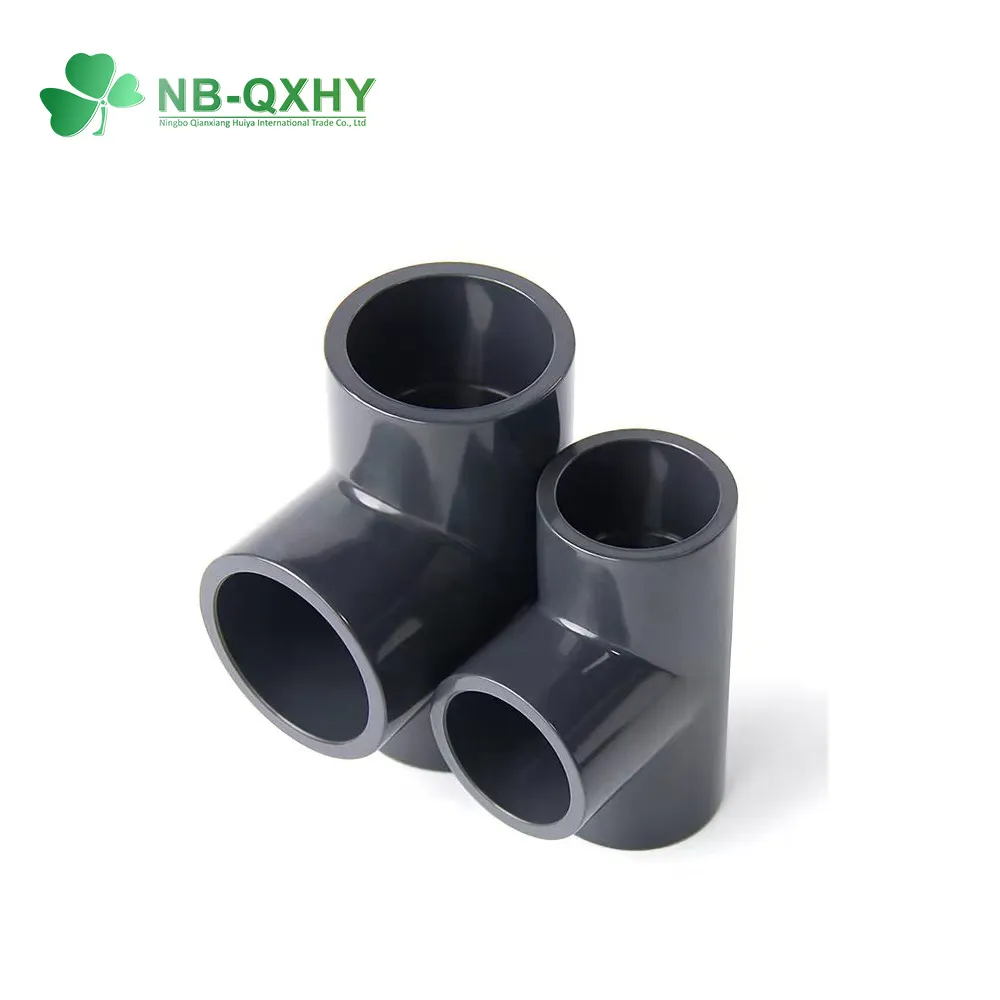

UPVC Industrial Pipe Fittings

UPVC Industrial Pipe Fittings Manufacturer

There are two types of our water supply pipe fittings, one is the conventional type, which has a thinner wall thickness and lighter weight, but the price is more advantageous. One is industrial grade pipe fittings, which have thicker walls and better quality, which can well meet the needs of chemical scenarios. According to different situations, our factory has a variety of products with different prices and types to choose from, which can well cover the needs of most customers. Please tell us your requirements, we can provide product catalog and latest price list.

Industrial Pipe Fittings Information

| Product Name | Industrial Pipe Fittings | Color | Grey, or Customized | |

| Main Material | UPVC | Pressure | PN10/16 | |

| Size | DN15-DN400 | Packing | Standard Export Packaging or as Your Request | |

| Main Market | South America, Southeast Asia, Middle East, Africa | Use | Water Supply | |

| Connection | Socket | Origin | Ningbo, Zhejiang, China | |

| Customized Support | OEM, ODM | Port | Ningbo/Shanghai | |

| Technics | Injection | Lead Time | 25-35 Days | |

| Certificate | ISO | Sample | Free |

Industrial Pipe Fittings Specification

| Product Name | Specification | Packaging Quantity | Weight | Box Size |

| (mm) | (PCS/Box) | |||

| Coupling | DN15(φ20) | 80*24=1920 | 12 | 480*360*360 |

| DN20(φ25) | 80*14=1120 | 18 | 480*360*360 | |

| DN25(φ32) | 30*20=600 | 29 | 480*360*360 | |

| DN32(φ40) | 476 | 52 | 455*352*408 | |

| DN40(φ50) | 252 | 87 | 435*365*415 | |

| DN50(φ63) | 150 | 149 | 460*385*415 | |

| DN65(φ75) | 80 | 231 | 460*360*390 | |

| DN80(φ90) | 48 | 349 | 435*330*450 | |

| DN100(φ110) | 27 | 589 | 395*395*400 | |

| DN125(φ140) | 18 | |||

| DN150(φ160) | 12 | |||

| DN200(φ225) | 4 | |||

| DN250(φ280) | 4 | |||

| DN300(φ315) | 4 | |||

| DN350(φ355) | 1 | |||

| DN400(φ400) | 1 | |||

| Elbow | DN15(φ20) | 80*16=1280 | 19 | 480*360*360 |

| DN20(φ25) | 40*19=760 | 30 | 480*360*360 | |

| DN25(φ32) | 20*20=400 | 50 | 480*360*360 | |

| DN32(φ40) | 15*15=225 | 88 | 480*360*360 | |

| DN40(φ50) | 128 | 148 | 495*360*375 | |

| DN50(φ63) | 75 | 258 | 545*375*340 | |

| DN65(φ75) | 48 | 404 | 530*375*400 | |

| DN80(φ90) | 24 | 616 | 450*430*310 | |

| DN100(φ110) | 20 | 1057 | 505*505*365 | |

| DN125(φ140) | 12 | |||

| DN150(φ160) | 6 | |||

| DN200(φ225) | 2 | |||

| DN250(φ280) | 2 | |||

| DN300(φ315) | 2 | |||

| DN350(φ355) | 1 | |||

| DN400(φ400) | 1 | |||

| Tee | DN15(φ20) | 50*16=800 | 26 | 480*360*360 |

| DN20(φ25) | 30*16=480 | 39 | 480*360*360 | |

| DN25(φ32) | 20*14=280 | 65 | 480*360*360 | |

| DN32(φ40) | 168 | 115 | 445*350*400 | |

| DN40(φ50) | 108 | 192 | 555*360*360 | |

| DN50(φ63) | 75 | 337 | 545*375*435 | |

| DN65(φ75) | 32 | 515 | 520*380*350 | |

| DN80(φ90) | 24 | 787 | 470*440*410 | |

| DN100(φ110) | 18 | 1348 | 560*390*485 | |

| DN125(φ140) | 6 | |||

| DN150(φ160) | 6 | |||

| DN200(φ225) | 2 | |||

| DN250(φ280) | 2 | |||

| DN300(φ315) | 1 | |||

| DN350(φ355) | 1 | |||

| DN400(φ400) | 1 | |||

| 45°Elbow | DN15(φ20) | 80*20=1600 | 16 | 480*360*360 |

| DN20(φ25) | 50*18=900 | 24 | 480*360*360 | |

| DN25(φ32) | 30*16=480 | 40 | 480*360*360 | |

| DN32(φ40) | 15*18=270 | 69 | 480*360*360 | |

| DN40(φ50) | 150 | 118 | 480*360*360 | |

| DN50(φ63) | 100 | 204 | 545*375*340 | |

| DN65(φ75) | 60 | 313 | 530*375*400 | |

| DN80(φ90) | 44 | 476 | 470*440*410 | |

| DN100(φ110) | 24 | 807 | 505*505*365 | |

| Reducing Coupling | DN20*15(φ25*20) | 80*16=1280 | 17 | 480*360*360 |

| DN25*15(φ32*20) | 50*17=850 | 25 | 480*360*360 | |

| DN25*20(φ32*25) | 50*16=800 | 27 | 480*360*360 | |

| DN32*15(φ40*20) | 30*16=480 | 41 | 480*360*360 | |

| DN32*20(φ40*25) | 30*15=450 | 42 | 480*360*360 | |

| DN32*25(φ40*32) | 30*14=420 | 45 | 480*360*360 | |

| DN40*15(φ50*20) | 420 | 69 | 435*365*415 | |

| DN40*20(φ50*25) | 420 | 70 | 435*365*415 | |

| DN40*25(φ50*32) | 420 | 72 | 435*365*415 | |

| DN40*32(φ50*40) | 420 | 78 | 435*365*415 | |

| DN50*20(φ63*25) | 240 | 119 | 460*385*415 | |

| DN50*25(φ63*32) | 240 | 120 | 460*385*415 | |

| DN50*32(φ63*40) | 240 | 126 | 460*385*415 | |

| DN50*40(φ63*50) | 240 | 131 | 460*385*415 | |

| DN65*20(φ75*25) | 120 | 180 | 460*360*360 | |

| DN65*25(φ75*32) | 120 | 182 | 460*360*360 | |

| DN65*40(φ75*50) | 120 | 193 | 460*360*360 | |

| DN65*50(φ75*63) | 80 | 209 | 460*360*390 | |

| DN80*40(φ90*50) | 72 | 288 | 435*330*425 | |

| DN80*50(φ90*63) | 72 | 295 | 435*330*425 | |

| DN80*65(φ90*75) | 72 | 320 | 435*330*425 | |

| DN100*40(φ110*50) | 60 | 472 | 520*395*430 | |

| DN100*50(φ110*63) | 60 | 483 | 520*395*430 | |

| DN100*65(φ110*75) | 60 | 499 | 520*395*430 | |

| DN100*80(φ110*90) | 60 | 522 | 520*395*430 | |

| Union | DN15(φ20) | 20*19=380 | 61 | 460*390*275 |

| DN20(φ25) | 12*20=240 | 86 | 460*390*275 | |

| DN25(φ32) | 9*16=144 | 136 | 460*390*275 | |

| DN32(φ40) | 100 | 191 | 420*340*397 | |

| DN40(φ50) | 100 | 278 | 485*390*435 | |

| DN50(φ63) | 48 | 400 | 475*357*390 | |

| DN65(φ75) | 27 | 807 | 445*445*380 | |

| DN80(φ90) | 27 | 1363 | 510*340*470 | |

| DN100(φ110) | 8 | 1969 | 395*395*365 | |

| Reducing Bushing | DN20*15(φ25*20) | 200*20=4000 | 480*360*360 | |

| DN25*15(φ32*20) | ||||

| DN25*20(φ32*25) | 100*22=2200 | 10 | 480*360*360 | |

| DN32*20(φ40*25) | ||||

| DN32*25(φ40*32) | 50*24=1200 | 17 | 480*360*360 | |

| DN40*25(φ50*32) | ||||

| DN40*32(φ50*40) | 30*20=600 | 32 | 480*360*360 | |

| DN50*20(φ63*25) | ||||

| DN50*25(φ63*32) | ||||

| DN50*32(φ63*40) | ||||

| DN50*40(φ63*50) | 20*16=320 | 61 | 480*360*360 | |

| DN65*40(φ75*50) | ||||

| DN65*50(φ75*63) | 196 | 81 | 475*348*320 | |

| DN80*25(φ90*32) | ||||

| DN80*50(φ90*63) | ||||

| DN80*65(φ90*75) | 140 | 135 | 465*347*380 | |

| DN100*40(φ110*50) | ||||

| DN100*50(φ110*63) | 60 | 240 | 455*330*320 | |

| DN100*65(φ110*75) | ||||

| DN100*80(φ110*90) | 84 | 314 | 435*337*440 | |

| DN125*100(φ140*110) | 36 | |||

| DN150*50(φ160*63) | ||||

| DN150*63(φ160*75) | ||||

| DN150*100(φ160*110) | 24 | |||

| DN150*125(φ160*140) | 36 | |||

| DN200*100(φ225*110) | 6 | |||

| Blind Plate | DN40(φ50) | 60 | 389 | 305*305*265 |

| DN50(φ63) | 48 | 533 | 335*335*220 | |

| DN65(φ75) | 36 | 818 | 378*378*200 | |

| DN80(φ90) | 32 | 977 | 410*410*195 | |

| DN100(φ110) | 32 | 1294 | 448*448*200 | |

| DN125(φ140) | ||||

| DN150(φ160) | ||||

| DE200(φ200) | ||||

| DN200(φ225) | ||||

| Flange | DN40(φ50) | 66 | 315 | 460*305*455 |

| DN50(φ63) | 48 | 439 | 505*335*370 | |

| DN65(φ75) | 42 | 640 | 563*378*365 | |

| DN80(φ90) | 24 | 787 | 410*410*335 | |

| DN100(φ110) | 20 | 1082 | 448*448*365 | |

| DN125(φ140) | 16 | 1520 | 505*505*350 | |

| DN150(φ160) | 12 | 2110 | 570*570*297 | |

| DN200(φ225) | 6 | |||

| Reducing Tee | DN20*15(φ25*20) | 15*12=600 | 34 | 480*360*360 |

| DN25*15(φ32*20) | 30*12=360 | 52 | 480*360*360 | |

| DN25*20(φ32*25) | 30*12=360 | 56 | 480*360*360 | |

| DN32*15(φ40*20) | 55*5=275 | 78 | 450*350*390 | |

| DN32*20(φ40*25) | 53*5=265 | 85 | 455*350*415 | |

| DN32*25(φ40*32) | 50*5=250 | 97 | 465*350*450 | |

| DN40*20(φ50*25) | 36*4=144 | 129 | 430*385*380 | |

| DN40*25(φ50*32) | 41*4=164 | 146 | 500*385*415 | |

| DN40*32(φ50*40) | 36*4=144 | 165 | 520*385*440 | |

| DN50*20(φ63*25) | 30*4=120 | 207 | 480*395*425 | |

| DN50*25(φ63*32) | 120 | 226 | 520*395*455 | |

| DN50*32(φ63*40) | 75 | 248 | 500*395*370 | |

| DN50*40(φ63*50) | 75 | 283 | 520*395*400 | |

| DN65*20(φ75*25) | 80 | 302 | 465*375*485 | |

| DN65*25(φ75*32) | 60 | 325 | 470*375*390 | |

| DN65*40(φ75*50) | 48 | 396 | 475*375*445 | |

| DN65*50(φ75*63) | 48 | 452 | 500*375*480 | |

| DN80*25(φ90*32) | 36 | 460 | 435*330*435 | |

| DN80*40(φ90*50) | 36 | 541 | 490*330*480 | |

| DN80*50(φ90*63) | 36 | 604 | 560*330*525 | |

| DN80*63(φ90*75) | 24 | 682 | 445*435*375 | |

| DN100*40(φ110*50) | 24 | 859 | 510*440*365 | |

| DN100*50(φ110*63) | 24 | 937 | 510*460*385 | |

| DN100*65(φ110*75) | 18 | 1035 | 500*400*420 | |

| DN100*80(φ110*90) | 18 | 1152 | 520*400*445 | |

| End Cap | DN15(φ20) | 20*180=3600 | 8 | 480*360*360 |

| DN20(φ25) | 20*100=2000 | 13 | 480*360*360 | |

| DN25(φ32) | 20*50=1000 | 21 | 480*360*360 | |

| DN32(φ40) | 20*30=600 | 37 | 480*360*360 | |

| DN40(φ50) | 460 | 63 | 435*357*415 | |

| DN50(φ63) | 240 | 110 | 460*385*415 | |

| DN65(φ75) | 140 | 175 | 460*360*390 | |

| DN80(φ90) | 84 | 164 | 435*330*450 | |

| DN100(φ110) | 45 | 420 | 395*395*400 | |

| Female Coupling | DN15(φ20) | 100*16=1600 | 14 | 475*340*330 |

| DN20(φ25) | 60*16=960 | 21 | 475*340*330 | |

| DN25(φ32) | 30*22=660 | 33 | 490*415*315 | |

| DN32(φ40) | 20*20=400 | 54 | 490*415*315 | |

| DN40(φ50) | 192 | 83 | 410*320*335 | |

| DN50(φ63) | 120 | 141 | 475*348*320 | |

| DN65(φ75) | 100 | 217 | 465*370*390 | |

| DN80(φ90) | 60 | 309 | 435*337*440 | |

| DN100(φ110) | 48 | 501 | 532*398*420 | |

| Male Coupling | DN15(φ20) | 100*18=1800 | 14 | 475*340*330 |

| DN20(φ25) | 60*16=960 | 21 | 475*340*330 | |

| DN25(φ32) | 30*22=660 | 34 | 490*415*415 | |

| DN32(φ40) | 20*20=400 | 55 | 490*415*415 | |

| DN40(φ50) | 256 | 85 | 410*320*335 | |

| DN50(φ63) | 168 | 153 | 475*348*320 | |

| DN65(φ75) | 120 | 223 | 465*347*380 | |

| DN80(φ90) | 80 | 323 | 435*337*440 | |

| DN100(φ110) | 48 | 538 | 532*398*438 | |

| Union Ball Valve(PVC/PPH) | DN15(φ20) | 100 | 180 | 412*292*440 |

| DN20(φ25) | 75 | 239 | 462*327*327 | |

| DN25(φ32) | 48 | 383 | 436*316*417 | |

| DN32(φ40) | 36 | 559 | 381*356*468 | |

| DN40(φ50) | 24 | 826 | 432*408*346 | |

| DN50(φ63) | 18 | 1236 | 513*378*378 | |

| DN65(φ75) | 8 | 2701 | 436*312*508 | |

| DN80(φ90) | 6 | 4114 | 531*484*314 | |

| DN100(φ110) | 4 | 5754 | 542*406*349 | |

| Foot Valve | DN40(φ50) | 20 | ||

| DN50(φ63) | 18 | |||

| DN65(φ75) | 10 | |||

| DN80(φ90) | 9 | 1775 | 545*540*325 | |

| DN100(φ110) | 6 | 2605 | 620*415*385 | |

| DN125(φ140) | 4 | 5570 | 530*530*490 | |

| DN150(φ160) | 2 | 6530 | 575*295*515 | |

| DN200(φ200) | 2 | |||

| Electric Ball Valve | DN15(φ20) | 5 | ||

| DN20(φ25) | 5 | |||

| DN25(φ32) | 5 | |||

| DN32(φ40) | 3 | |||

| DN40(φ50) | 3 | |||

| DN50(φ63) | 3 | |||

| DN65(φ75) | 3 | |||

| DN80(φ90) | 2 | |||

| DN100(φ110) | 2 |

Industrial Pipe Fittings Package

Generally speaking, our small-sized pipe fittings are packed in inner bags, and large-sized pipe fittings are directly packed in outer packaging. At the same time, the outer box is packed in imported three-layer corrugated cardboard boxes, which can effectively avoid damage or collision during product handling and transportation.

In addition, we can print the outer box according to the customer’s trademark design to achieve customized packaging.

Industrial Pipe Fittings Market

Our PN10/PN16 UPVC industrial pipe fittings are mainly used in South America, Southeast Asia, Middle East, Africa and other regions. South America mainly needs dark gray UPVC pipe fittings, Southeast Asia mainly needs blue UPVC pipe fittings with small size and light weight, the Middle East mainly needs PN16 pipe fittings, and Africa and Europe mainly need UPVC flexible pipe fittings.

Industrial Pipe Fittings Advantage

PN10/PN16 UPVC industrial pipe fittings can be mainly used in water supply pipeline systems under different working pressures, with the advantages of convenient connection, stable use and environmental protection.

Our Certifications

Our Service

1. Our pipe fitting molds are complete, which can meet the needs of customers for pipe fittings of different sizes. At the same time, we can provide samples according to customer requirements, and open the mold to produce pipe fittings of special size or special color.

2. We can carry out laser marking on pipe fittings or marking on molds for customers to help customers expand their brand influence.

3. We give priority to the production of orders for customers, and have a stable delivery time.

4. We have professional product engineers who can solve any product problems you encounter during sales or use at any time.

5. We can produce pipes to be used and sold together with our fittings.

6. Our products are certified by ISO: 9001, SGS, BV, CE and other professional testing organizations.

7. We support free samples to directly check the quality of our products.